ماكينات المعادن

قسم ماكينات المعادن و الذي يحتوي علي ماكينات البلازما و الفيبر ليزر بمختلف الاحجام و قدرات القطع ليناسب كافة العملاء

ماكينات الأخشاب

يحتوي قسم ماكينات الأخشاب و الخامات الغير معدنية علي العديد من الماكينات و الراوتر و التي تعمل علي خامات مختلفة و يتم صناعتها بعناية و دقة فائقة للوصول لأفضل النتائج

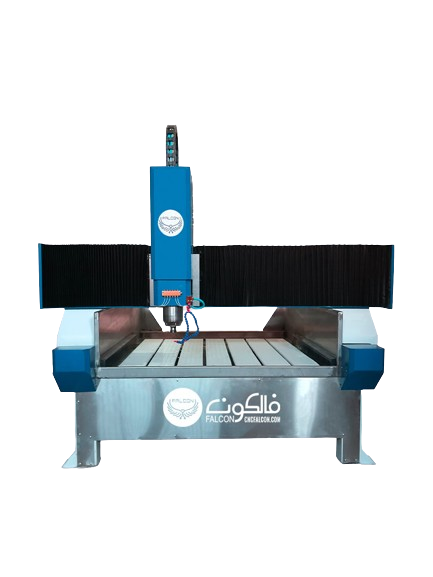

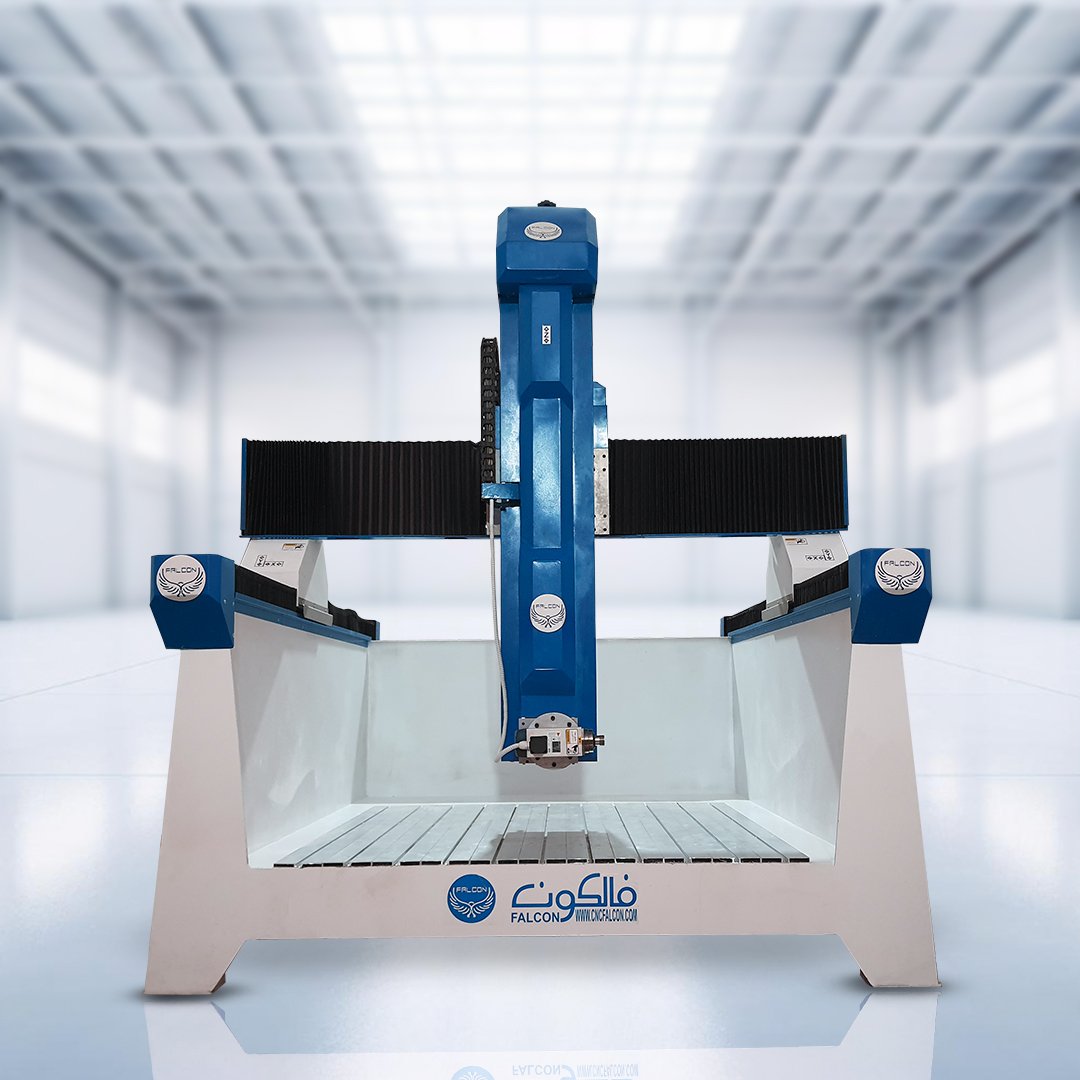

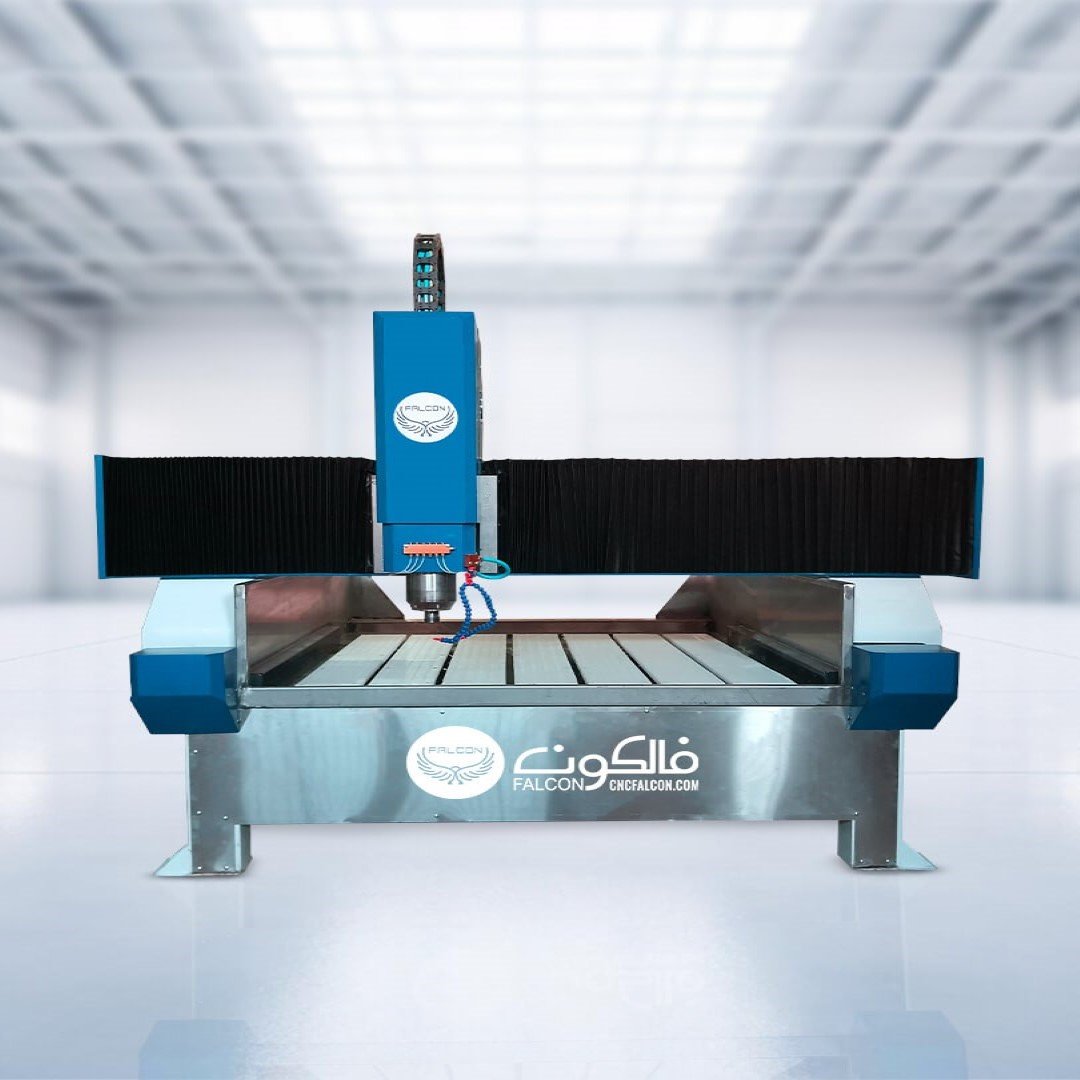

ماكينات الرخام و الأحجار

يحتوي قسم الرخام علي ماكينات التحكم الرقمي cnc و راوتر الرخام بكافة اشكاله و أحجامها المختلفة لتلبي كافة الاحتياجات

ماكينات التحكم الرقمي من فالكون

راوتر أخشاب

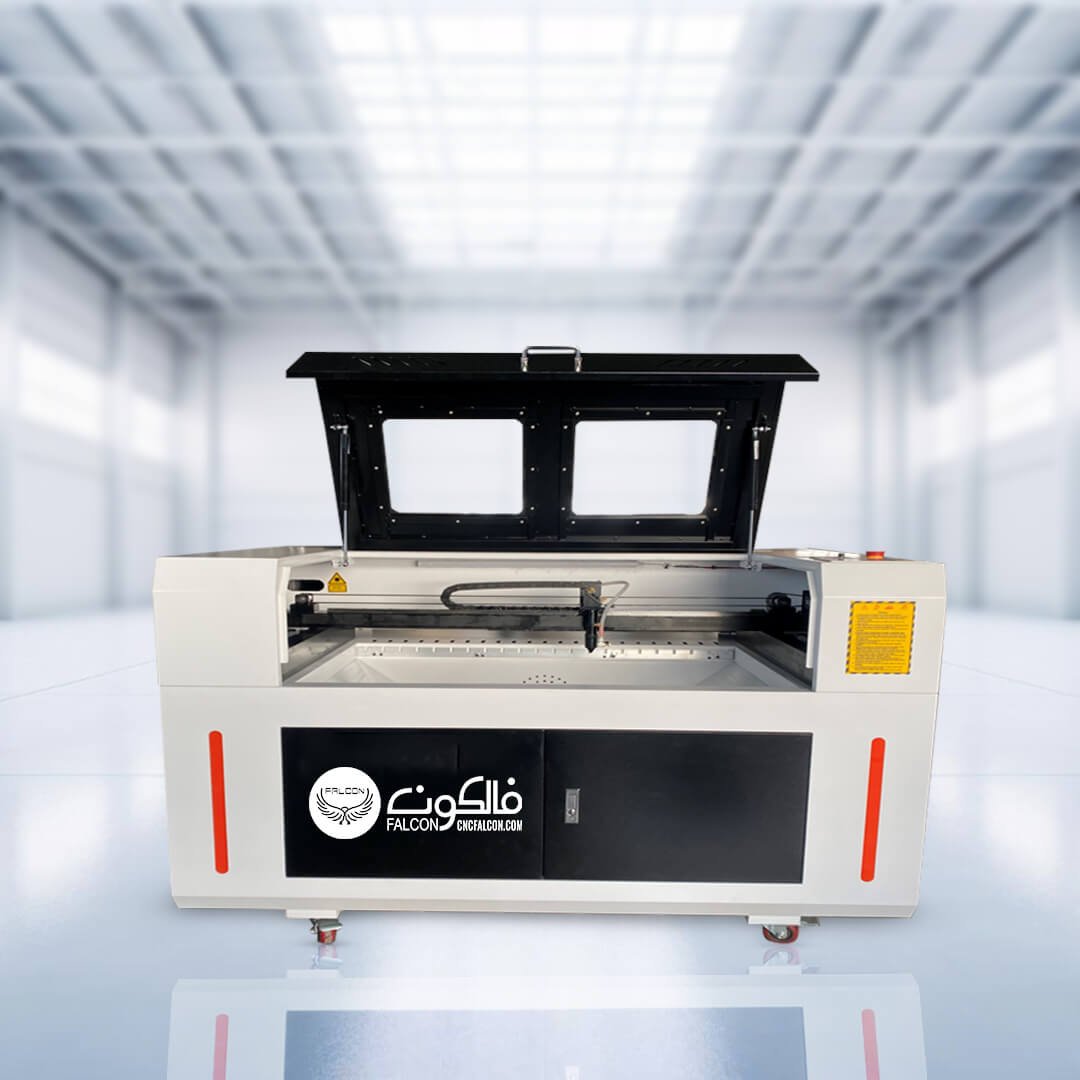

ماكينة ليزر Co2

ماكينة لصق الشريط

ماكينة الفور اكس

مقطع الأخشاب

راوتر متعدد الرؤوس

مخرطة CNC

راوتر رخام

ماكينة فايبر ليزر

ماكينة بلازما

ماكينة ماركر

الرؤية و الرسالة

رؤيتنا ان نكون داعم للصناعات العربية و نقدم افضل ما توصلت اليه التكنولوجيا في المجال الصناعي للشركات و المصانع العربية لننهض بها

رسالتنا تقديم منتجات ذات جوده عالمية و مساعدة عملائنا لتحقيق اهدافهم الصناعية بأفضل قيمة ممكنة

الثقة

نقدم منتجات ذات جودة عالية يمكنك الإعتماد عليها بشكل تام

أفضل قيمة مقابل سعر

نقدم أفضل قيمة مقابل سعر فاهتمامنا بالجودة و بتقديم المنتجات بسعر تنافسي في نفس الوقت

السرعة و الانتاجية

نعمل علي مدار الساعة لنقدم لعملائنا المنتجات في الوقت المناسب دون تأخير

ضمان يرضيك

لدينا فريق كامل لتقديم الضمان و خدمات ما بعد البيع لضمان أقصي استفادة لعملائنا الكرام

شركاء نجاح فالكون

آراء العملاء

تواصل معنا

تواصل معنا الأن و سيقوم أحد مندوبينا بالرد عليك في اسرع وقت ممكن